ALUMINIUM FINISHES

Powder Coated Finish

Powder coated aluminum windows are painted using a dry process with polyester powder, hence the term “powder” coated. In this process an electrical charge is applied to the aluminum bar and the powder is sprayed onto it. The electrical charge bonds the powder to the aluminum and once applied the powder paint is cured in an oven.

There are approximately 200 polyester powder coat colors available including matt, gloss, textured, and specialist finishes.

MATTE FINISHES

Matte finishes, also known as flat finishes, have a low level of shine or reflection. Matte finishes are achieved by using a specific type of paint or coating that scatters light rather than reflecting it directly. This scattering of light creates a smooth, non-reflective surface.

GLOSSY FINISHES

Glossy finishes, on the other hand, are characterized by their high shine and reflective surface. These finishes create a polished and vibrant look for aluminium doors and windows. Glossy finishes are achieved by using coatings that allow light to be reflected directly, creating a mirror-like effect.

TEXTURED FINISHES

Textured finishes, these are characterized by their dull shine and reflective surface. They gives a grain like feeling on touching.

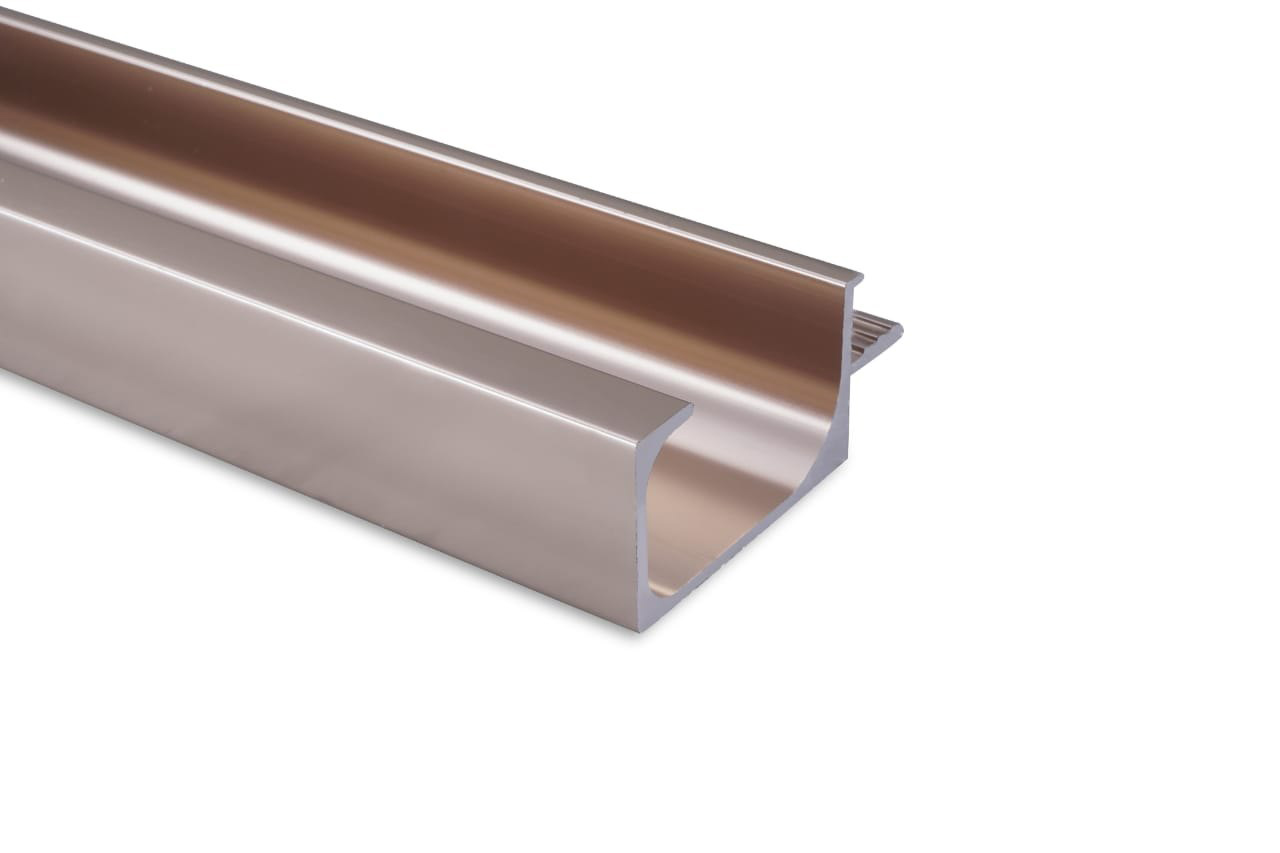

ANODISED FINISH

Anodizing is an electrochemical process by which a metallic surface is converted into a corrosion-resistant, durable, and aesthetically pleasing finish. The anodizing process helps to protect metal against wear and corrosion while also improving itsappearance.The anodizing process consists of applying a thin oxide film to the metal surface through an electrochemical process. The metal acts as the anode in an acid bath solution and an electrical current is then sent through the bath to cause the formation of tightly adherent metal oxide on the anode surface.

WOOD FINISH

Wood finish aluminum is a type of aluminum that has been designed to resemble wood. It is often used in construction and home decor projects where a wood-like appearance is desired but the durability of aluminum is also needed.